Email:info@goodfuturesolar.com

Tel: +86-371-63966669

Email:info@goodfuturesolar.com

Tel: +86-371-63966669

Discover Good Future’s Zn-Al-Mg Solar Bearings — engineered for superior corrosion resistance, high strength, and long lifespan. Made with advanced Zinc-Aluminum-Magnesium coated steel, these bearings ensure stable performance for solar tracking systems in harsh outdoor environments.

Protect your solar investment with the Good Future Solar Tracker Controller. Features high wind, snow, voltage, and limit angle protection for reliable year-round performance.

pisc-33 GF Controller Catalog

A solar tracking controller is a control device used to drive a solar tracking system. It automatically adjusts the angle of solar panels based on the real-time position of the sun, ensuring that photovoltaic panels are always aligned at the optimal angle to the sun, thereby improving photovoltaic power generation efficiency. Compared to fixed solar panels, photovoltaic systems equipped with tracking controllers can increase power generation by 10% to 35%, with the advantage being more pronounced during early mornings, evenings, or in winter when sunlight is weaker. A solar tracking controller uses built-in sensors, clock chips, or algorithms to calculate the sun’s position in real time and control the motor to rotate the mounting bracket. Common control methods include: Light-sensing: Uses light-sensitive sensors to detect light intensity and automatically adjust the angle. Astronomical algorithm: Calculates the sun’s trajectory based on geographical coordinates, time, and date to achieve precise tracking. Hybrid control: Combines light sensing and astronomical algorithms to ensure high-precision tracking around the clock. Advantages of solar tracking controllers Enhanced power generation efficiency: Maximises the utilisation of solar radiation. Intelligent management: Supports automatic detection, fault alerts, and remote monitoring. Extended equipment lifespan: Intelligent regulation prevents mechanical overuse. Flexible compatibility: Applicable...

GF Solar Tracker Controller: Stable and Smart, Accelerating Global PV Project Deployment As the solar industry increasingly demands higher efficiency and lower O&M costs, GF New Energy’s solar tracker controller—designed specifically for tracking systems—is becoming a trusted choice for developers, EPCs, and integrators around the world. Combining stability, intelligence, and fast deployment, it empowers your PV project from day one. 🔧 Core Features Cloud Platform Support The controller supports cloud connectivity, enabling real-time remote monitoring, parameter adjustment, and fault alerts—helping operators manage the power plant more efficiently and reduce O&M workload. Backtracking Algorithm Equipped with an intelligent backtracking logic that minimizes row-to-row shading during early morning and late afternoon, enhancing energy yield. Best suited for flat terrain and standard system layouts. Easy-to-Change Battery Modular battery design allows for quick and easy replacement in the field, reducing maintenance complexity and improving long-term system reliability. ✅ Key Advantages No MOQ Flexible order quantities allow quick deployment, even for pilot projects or small-scale installations. Customization Available We offer tailor-made solutions including control logic, communication protocols, and hardware interfaces to meet specific project requirements. CE & ISO Certified Our controllers meet international standards and are certified for use in major global markets, ensuring safety and...

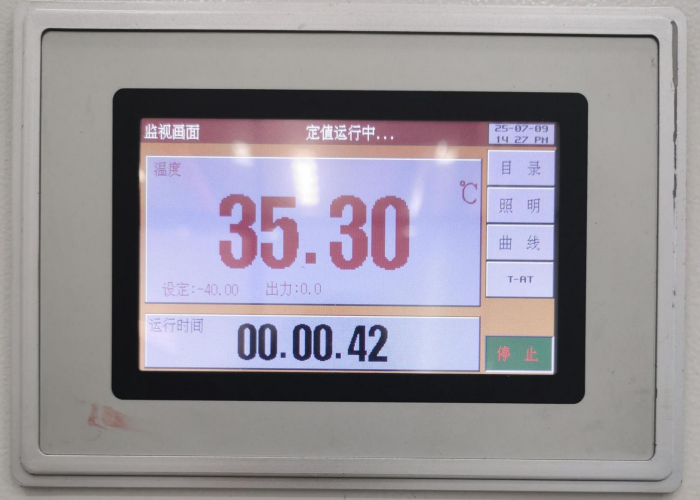

To ensure that our products can perform under harsh conditions, GF Solar recently conducted a low-temperature performance test on our DC Tracker Control Unit (TCU). The objective: verify stable operation in sub-zero temperatures for an extended duration. Experimental overview ▍Test Purpose: – To verify whether the TCU device functions normally after low-temperature treatment. ▍Testing is conducted in accordance with the following standards: – The test procedures and criteria for evaluating test results are based on Chapter 16, Section 16.1 “Low-Temperature Test” of GB/T 29320-2024 “Technical Requirements for Solar tracking systems in Photovoltaic Power Plants.” ▍Test Sample: – Equipment Name: Tracking Control Unit (TCU) – Model Specification: GF-S-TCU-V1.0 – Quantity: 1 set ▍Test Date and Location: – July 9, 2025 – No. 2 Courtyard, Southeast Corner of the Intersection of Dehui Street and Wenjin North Road, Zheng’an Town, Zhongmu County, Zhengzhou, Henan ▍Test system: – TCU control unit: Model GF-S-TCU-V1.0, 1 set – Tracking system type: Single-axis solar mounting system (including flat single-axis and inclined single-axis) – Tracking mechanism composition: · Electric Actuator: DC 24V motor with gear reduction mechanism · Steel Structure Mounting System, Flat Single-Axis, supporting ±60° rotation · Installation Components: 1P total of 9 solar panels ▍Experimental Equipment: – High-Low Temperature Test Chamber...