Email:info@goodfuturesolar.com

Tel: +86-371-63966669

Email:info@goodfuturesolar.com

Tel: +86-371-63966669

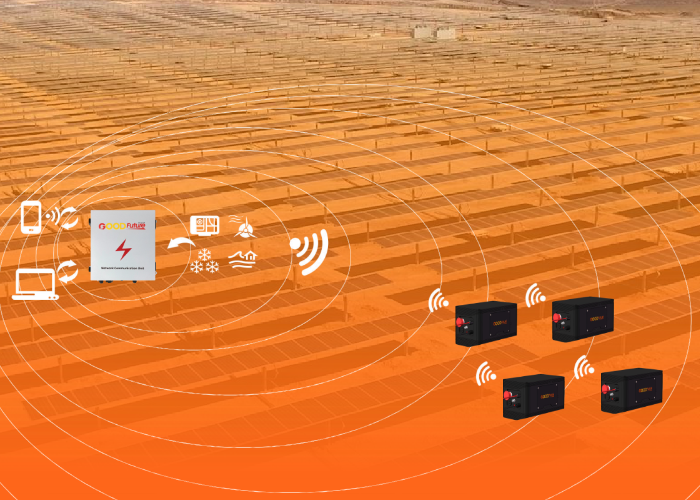

What’s the Relationship Between TCU and NCU in a Solar Tracker System? In a solar tracker system, both the TCU (Tracker Control Unit) and NCU (Network Control Unit) play essential roles — working together like the “field operator” and the “command center.” ▪️ TCU (Tracker Control Unit) Installed on individual trackers or tracker groups Controls motors to adjust the tilt angle based on solar position Collects sensor data and executes tracking algorithms Operates locally, can support offline tracking if needed ▪️ NCU (Network Control Unit) Installed at a centralized location in the solar plant Manages and monitors multiple TCUs across the site Connects to SCADA/cloud platforms for remote control and data management Acts as the communication hub between TCUs and the control center ▪️ How They Work Together NCU receives instructions from the SCADA/cloud It distributes commands to each TCU TCUs drive the motors and report status back to the NCU NCU aggregates data and uploads it to the control platform 8. ▪️ Think of it this way: NCU = The brain, managing the big picture TCU = The hands, executing real-time motion Together, they ensure your solar tracking system stays efficient, responsive, and intelligent.

In utility-scale solar tracker systems, bearings are more than just components—they are the backbone of structural reliability and long-term performance. While some solutions rely on plastic bearings for lower upfront costs, aluminum bearings are increasingly becoming the industry’s preferred option.

When it comes to setting up a solar power system, selecting the right solar tracker is crucial for maximizing energy efficiency and ensuring a reliable, long-term operation. However, one key factor that often gets overlooked is system compatibility. Here’s why it should be a top consideration when choosing a solar tracker: 1. Seamless Integration with Existing Components The most important thing to consider when purchasing a solar tracker is whether it will integrate smoothly with your existing solar components. Solar systems typically consist of various parts, including panels, inverters, controllers, and battery storage systems. A tracker that isn’t fully compatible with these components can lead to operational inefficiencies, potential system failures, or increased costs for additional modifications. Our GF Solar Tracker Controller has been specifically designed for easy integration with a variety of solar systems, ensuring seamless performance across the board. Whether you’re upgrading your existing setup or starting fresh, our controller makes installation hassle-free and helps you get the most out of your solar investment. 2. Maximizing Performance through Compatibility A tracker that works well with your system maximizes the performance of your solar panels. The best trackers adapt to your environment, adjusting the solar panels to face the...

When designing a reliable and long-lasting solar tracking system, selecting the right bearing material is crucial. Aluminum spherical bearings stand out as the ideal choice due to their superior mechanical properties, thermal stability, and resistance to harsh environmental conditions. 1. High Strength with Lightweight Performance Aluminum spherical bearings are engineered to: Withstand high loads and mechanical stress. Maintain structural integrity under continuous movement. Reduce system strain due to their lightweight nature. This makes them more durable than traditional materials, which may deform or wear out over time. 2. Excellent Thermal Properties Solar trackers operate in environments with extreme temperature fluctuations. Aluminum bearings: Offer superior thermal conductivity, quickly dissipating heat. Prevent overheating and material degradation. Ensure smooth and stable operation even under intense sun exposure. 3. Outstanding Resistance to Corrosion, Dirt, and UV For outdoor applications, material resilience is essential. Aluminum bearings naturally: Form a protective oxide layer that prevents rust. Perform well in coastal, desert, or humid environments. Offer excellent UV and dirt resistance, maintaining performance with minimal maintenance. Unlike steel bearings, they don’t require coatings or frequent upkeep. 4. Wear Resistance & Self-Lubrication Many aluminum bearings are designed with: Self-lubricating liners, reducing friction. Low-maintenance performance, extending service life. Smooth...

How to Choose the Right Tracker Controller for Your Solar System? Selecting the right tracker controller is crucial for optimizing the performance and efficiency of your solar system. Here are the key factors you need to consider: Electrical Compatibility The voltage of the controller must match the battery bank voltage in your system, with common options being 12V, 24V, and 48V. Additionally, the input current rating of the controller should be equal to or greater than the output current from the solar array. This is typically 1.25 times the short-circuit current of the array to ensure reliable operation in varying sunlight conditions. The controller must also be capable of handling the maximum power output from your solar panels, ensuring no mismatch that could reduce system efficiency. Tracking Precision and Features Tracker controllers come with different tracking methods such as light sensor tracking and algorithm-based tracking. Accuracy is essential to improve solar energy capture, and controllers with high precision can significantly enhance performance, especially in large-scale installations. Additionally, ensure the controller includes robust protective features like overvoltage, undervoltage, overcurrent, short-circuit, reverse polarity, and temperature protection to safeguard the system and prolong its lifespan. Data Monitoring and Remote Management Modern tracker controllers...

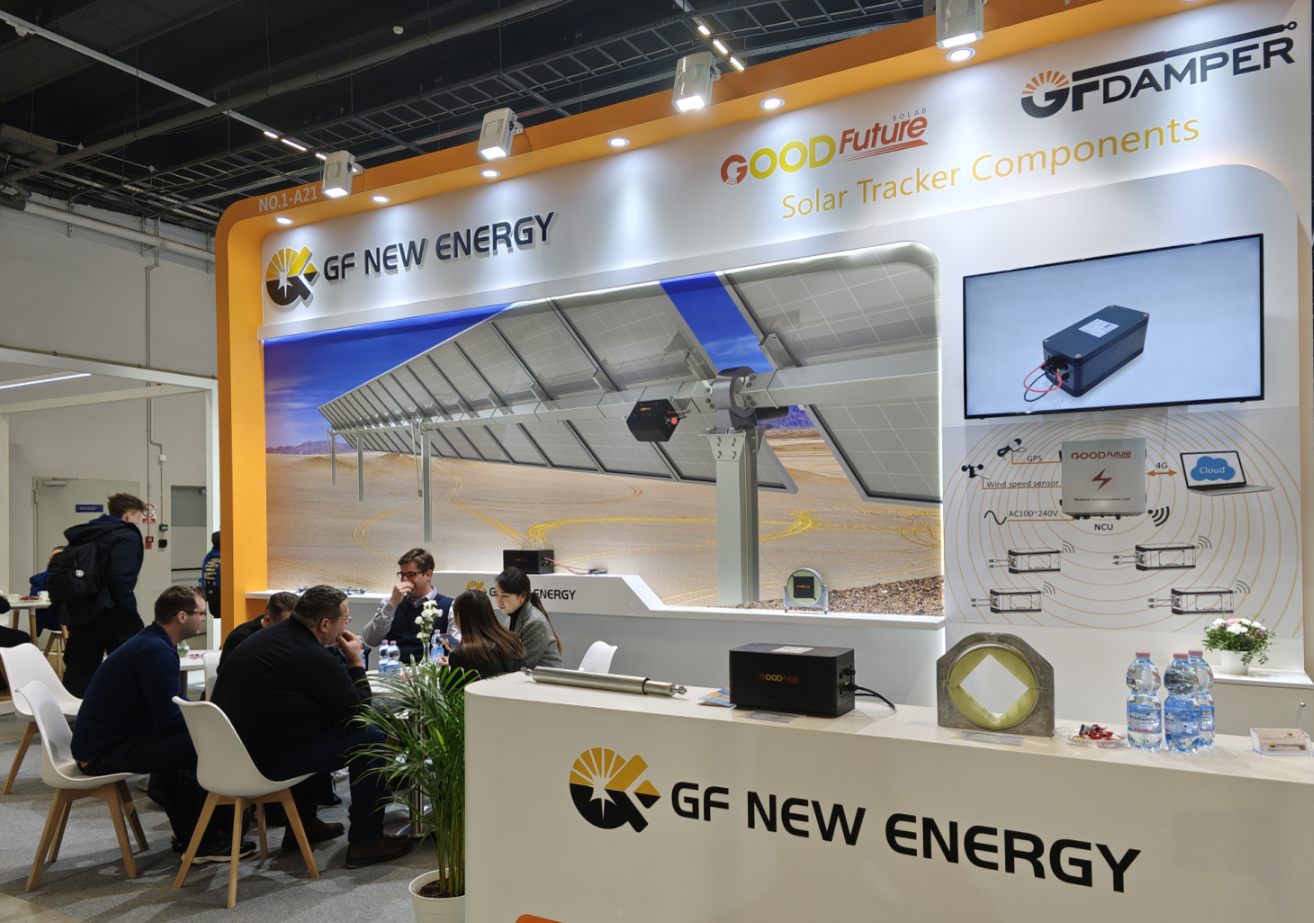

GF NEW ENERGY, a leading provider of solar tracking solutions, is committed to driving the global transition to renewable energy. At the 27th International Power Industry and Renewable Sources of Energy Fair (ENEX 2025) in Kielce, Poland, the company presented its cutting-edge solar tracker controllers, self-lubricating bearings, and high-performance dampers, all designed to optimize solar energy systems. Innovative Solar Tracking Solutions Unveiled at ENEX 2025 At ENEX 2025, GF NEW ENERGY showcased a range of products that enhance solar tracking systems’ efficiency and reliability. The company’s solar tracker controllers, powered by 3D backtracking algorithms, are designed to improve solar panel performance by reducing shading loss and optimizing energy output. Key features of GF NEW ENERGY’s solar tracker controllers include: Cloud Platform Integration: Remote monitoring and system adjustments ensure real-time control of solar installations. Easy-to-Replace Battery Design: Simplifying maintenance, reducing downtime, and enhancing system longevity. Smart Tracking Algorithms: These algorithms automatically adjust the panels’ positioning for maximum sun exposure. In addition to the controllers, GF NEW ENERGY also presented self-lubricating bearings and ZAM (Zinc-Aluminum-Magnesium) dampers, which boost the durability and stability of solar tracking systems. ZAM material in dampers helps resist harsh environmental conditions while significantly lowering maintenance requirements. Live Demonstrations:...